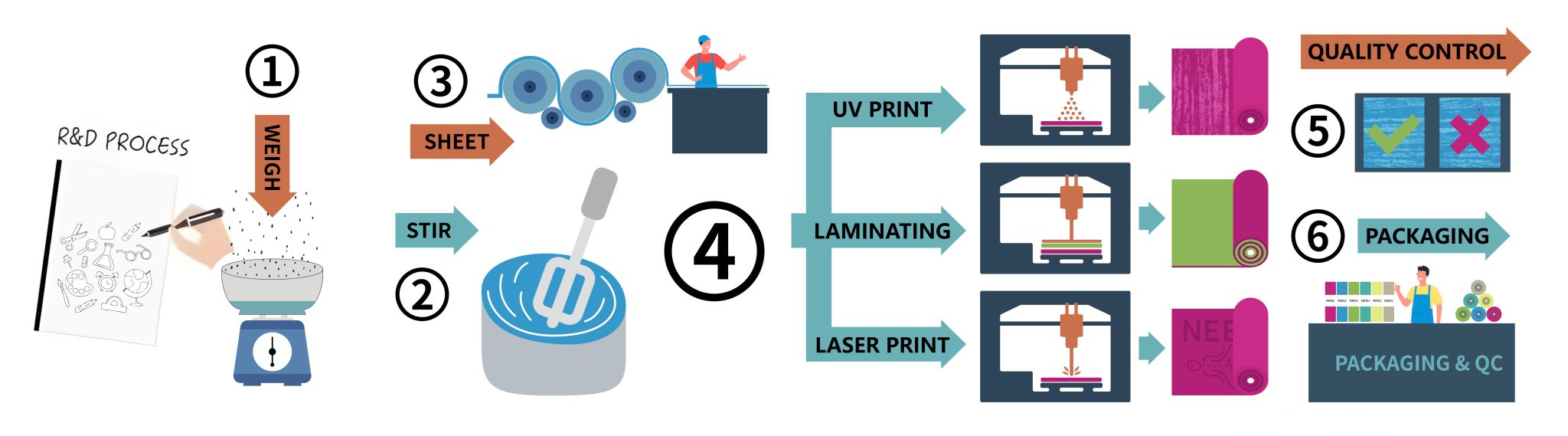

Complete TPE Yoga Mat Manufacturing Process

At our factory, we have a full set of TPE yoga mat production machines, ensuring high-quality manufacturing from start to finish. Our process includes everything from foam production, cutting, and logo customization, to the final packaging. Below, we’ll walk you through each step of the production process to give you a complete overview of how your perfect TPE yoga mat is made.

6 Basic Foam Manufacturing Steps for TPE Yoga Mats

1.TPE Yoga Mat Raw Material Formula

The process starts with the raw material formula. Ingredients are carefully measured and transferred from the ingredient room to the mixer, ensuring the right blend for high-quality TPE yoga mats.

2. Compounding Mixing Raw Materials

In the compounding step, the raw materials are placed into the mixer, where they are thoroughly blended to ensure a uniform and high-quality mixture. This step is crucial for achieving the right texture and durability in the final TPE yoga mat.

3.Extrusion (Shaping Foam into Semi-Finished Product)

In the extrusion step, the compounded foam material is mixed and then extruded into a sheet. This semi-finished product is ready for the next phase, where it will undergo foaming to form the final structure of the TPE yoga mat.

4.Weighing (Ensuring Consistent Product Weight)

In the weighing step, the semi-finished foam sheets are carefully weighed to ensure each piece has the same weight. This ensures consistency across all products before moving on to the next stage of production.

5.Foaming & Cooling (Shaping the Final Mat Structure)

In the foaming and cooling step, the semi-finished foam sheets are placed into the foaming machine, where they expand to form the final mat structure. After foaming, the mats are cooled to stabilize their shape and ensure durability.

6.Edge Trimming & Slicing (Preparing for Final Product)

In the edge trimming and slicing step, the foamed sheets are carefully trimmed to remove any excess material. This ensures that each piece is of consistent size, making it easier to process them into the final yoga mat shape.

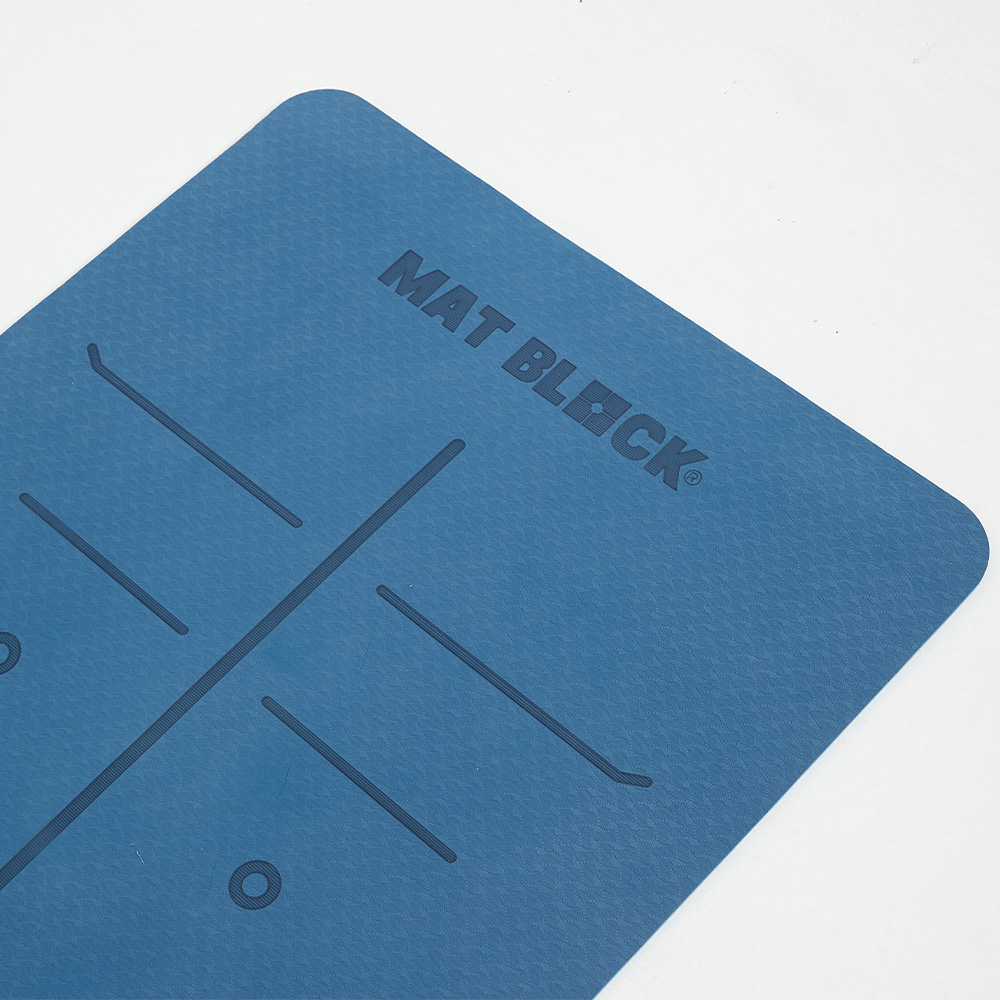

Laser Engraved Logo Yoga Mat

1: Embossing & Cutting (Custom Patterns and Sizes)

In the embossing process, the TPE base material is pressed with custom patterns using a specialized machine, enhancing both the mat’s texture and grip for better stability during practice. These patterns can be tailored to suit your specific needs, offering a personalized touch.

After embossing, the mats move to the cutting stage, where they are precisely cut to the required size. This ensures each mat meets the customer’s specifications, with the option for full customization in both design and dimensions.

2: Laser Engraving (Position Lines & Logo Customization)

In the laser engraving step, precision lasers are used to etch position lines and logos onto the surface of the TPE yoga mat. This ensures clear, sharp designs that are durable and won’t fade over time. The laser-engraved lines help with alignment during practice, while custom logos add a personal or branded touch to each mat.

Laser Engraved Logo Yoga Mat

[Click the image to see more details!]

Our Laser Engraved Logo Yoga Mats are crafted with precision and style. Click the image below to discover more about the design, material, and customization options.

Premium TPE Material: Eco-friendly, durable, and non-slip.

Custom Laser Engraving: Add your logo or design for a personal touch.

Perfect for Branding: Ideal for studios, gyms, and personal use.

Composite Tpe Yoga Mats

1: Thermal Lamination (Fusing Materials)

In the thermal lamination process, two different sheets of material are heated and pressed together, creating a seamless fusion. This technique enhances the durability and functionality of the yoga mat, ensuring a sturdy, multi-layered design tailored to meet customer needs.

2: Embossing & Cutting (Custom Patterns and Sizes)

In the embossing process, the TPE base material is pressed with custom patterns using a specialized machine, enhancing both the mat’s texture and grip for better stability during practice. These patterns can be tailored to suit your specific needs, offering a personalized touch.

After embossing, the mats move to the cutting stage, where they are precisely cut to the required size. This ensures each mat meets the customer’s specifications, with the option for full customization in both design and dimensions.

UV Printed Yoga Mats

1: Embossing & Cutting (Custom Patterns and Sizes)

In the embossing process, the TPE base material is pressed with custom patterns using a specialized machine, enhancing both the mat’s texture and grip for better stability during practice. These patterns can be tailored to suit your specific needs, offering a personalized touch.

After embossing, the mats move to the cutting stage, where they are precisely cut to the required size. This ensures each mat meets the customer’s specifications, with the option for full customization in both design and dimensions.

2:UV Printing (Logos & Colorful Patterns)

In the UV printing step, advanced UV printers are used to print logos or vibrant, colorful patterns directly onto the yoga mat. This process ensures high-definition results with excellent durability, allowing for custom designs that make each mat unique.

UV Printed Yoga Mats

Our UV Printed Yoga Mats allow you to showcase vibrant, eye-catching patterns or print your unique logo directly onto the mat. With high-definition UV printing, your designs will stay sharp and colorful, offering both style and durability for every practice.

Custom Logos & Designs: Print your brand or personal artwork.

Vibrant Colors: Stunning, long-lasting prints.

Durable & Non-Fading: Designed to withstand repeated use.

Elevate your yoga practice with a mat that’s as unique as you are!